ElectroCulture Magazine is your go-to resource for everything related to electroculture and the intriguing world of plant stimulation. In this article, we explore the critical function of wiring in electroculture, thereby revealing the potential for enhanced plant growth. Determine the intricate connections and pathways that allow electrical currents to reach plants, thereby stimulating their growth and productivity.

Examining the significance of proper insulation, voltage regulation, and monitoring systems for plant and human safety. Join us as we uncover the mysteries and possibilities of wiring for electroculture on this electrifying voyage. Together, let’s energize our understanding of plant cultivation!

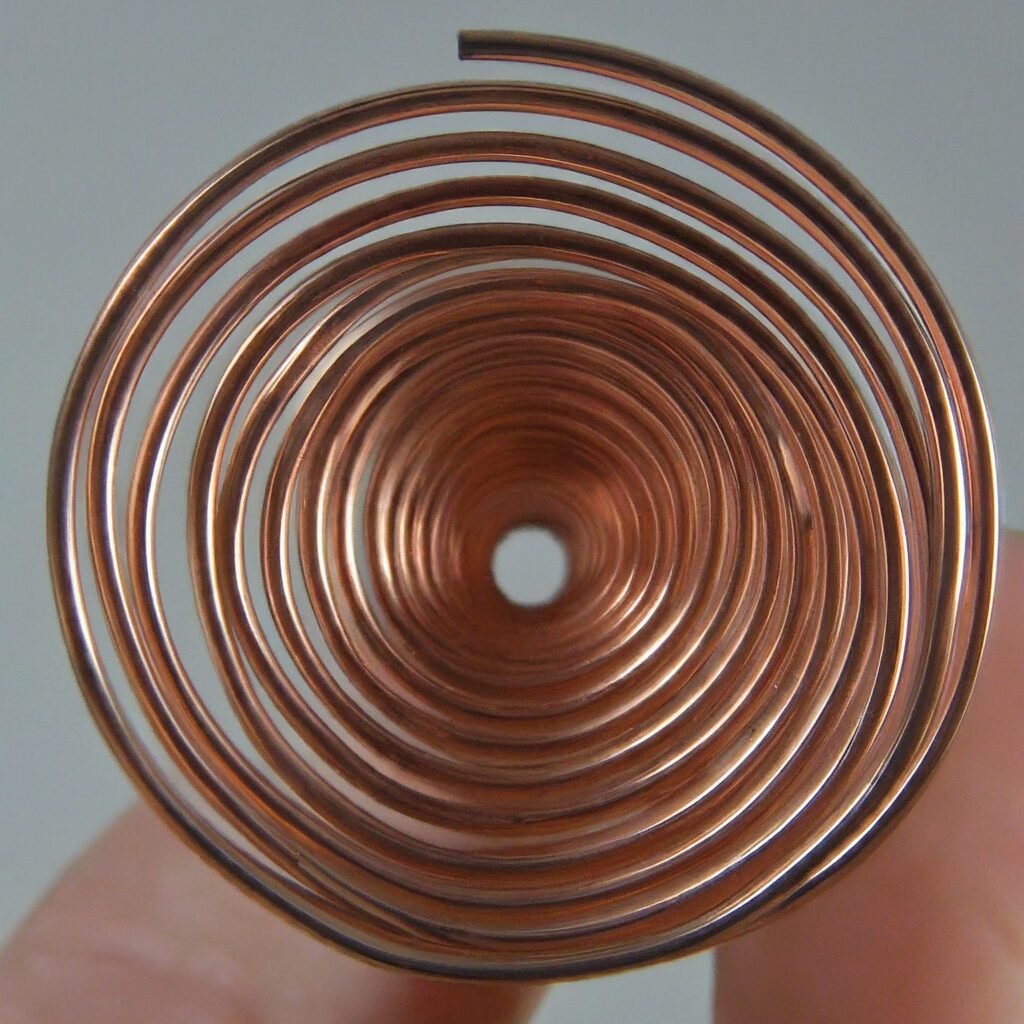

Review This Top 10 Copper Wire From Amazon..

Last update on 2024-06-28 / Affiliate links / Images from Amazon Product Advertising API

Basics

Wiring plays a crucial role in facilitating the application of electrical currents to vegetation in electroculture. The wiring system is responsible for the controlled delivery of electrical signals or currents to the facilities. Here are some important functions of wiring in electrotechnology:

- Conduction of electrical current: The conduit for the passage of electrical current from the power source to the plants is the wiring. It enables the current to reach the plant’s roots, stem, or foliage, depending on the electroculture technique employed.

- Placement of electrodes: Wiring is used to connect electrodes to the electricity source and appropriately position them. Electrodes are the locations where electricity is applied to plants. The wiring ensures that the electrodes are affixed to the plants securely and that the electrical connection is maintained.

- Safety and insulation: Wiring in electroculture systems must be adequately insulated to prevent plants from coming into direct contact with electrical components. Insulation protects plants from potential injury and reduces the likelihood of electric shocks or electrical system damage.

- Voltage regulation: The wiring system may include resistors, regulators, or controllers to regulate the voltage and current applied to the plants. This allows for precise control over the electrical stimulation, ensuring that the desired level of electrical energy is delivered to the plants without causing damage.

- Monitoring and feedback: Wiring can be used to integrate sensors or monitoring devices into the electroculture system for purposes of monitoring and feedback. These sensors can measure electrical conductivity, pH, temperature, and moisture content to provide feedback on the plant’s response to electrical stimulation. This feedback can aid in fine-tuning the electroculture setup and optimizing the applied electrical signals.

It is essential to note that the wiring requirements for electroculture can vary based on the technique and experimental setup chosen. To assure the well-being of the plants and individuals involved in the electroculture process, proper insulation, safety precautions, and careful design are essential.

Selection Criteria for Wiring in electroculture

Several criteria must be considered when selecting a metal for wiring in electroculture to ensure optimal performance and safety. Here are some important considerations:

- Conductivity: For efficient transmission of electrical currents, select a metal with a high electrical conductivity. Copper is a common material due to its high conductivity. Silver is even more conductive than copper, but is typically more expensive.

- Corrosion resistance: Since electroculture frequently exposes metals to moisture and soil, the chosen metal should have excellent corrosion resistance. The corrosion-resistant properties of stainless steel and copper make them suitable for use in electroculture wiring.

- Flexibility: The wiring material should be sufficiently flexible to facilitate installation and positioning. Copper or copper-clad aluminum conductors that are flexible and easy to use are frequently preferred.

- Safety: Ensure that the selected metal is secure for both the plants and the individuals participating in the electroculture process. Avoid metals that may leach noxious substances into the soil or negatively impact the health of the plant. Copper is generally regarded as secure for plants, but it is essential to conduct research or consult experts before implementing particular electroculture techniques.

- Durability :Choose a metal that can withstand the environmental conditions and mechanical duress of electroculture. To avoid frequent replacements or disruptions in the electrical system, the wiring material should be durable and long-lasting.

- Availability and cost: Consider the availability and cost of the metal, as it can have an effect on the viability of your electroculture endeavor. Copper is abundant and relatively inexpensive, making it a popular choice for numerous applications.

It is essential to note that different electroculture techniques may have specific wiring material requirements or recommendations. When choosing the final wiring metal, conduct extensive research, consult with experts, and take into account the specific requirements of your electroculture system.

Gauge Of Copper Wiring in Electroculture

Selecting the appropriate gauge (thickness) of copper wire for electroculture depends on several factors, including the electrical current requirements, distance of wiring, and the power source being used. Here are some guidelines to help you determine the gauge of copper wire for your electroculture setup:

- Current requirements: Determine the amount of electrical current needed for your electroculture application. This can vary depending on the specific technique and the desired stimulation level. Higher current requirements typically require thicker wire gauges to handle the increased load.

- Distance: Consider the distance between the power source and the plants or electrodes. Longer distances can result in increased resistance and voltage drop along the wire. Thicker wire gauges have lower resistance and can minimize voltage loss over longer distances.

- Power source: Take into account the voltage and amperage output of your power source. Higher voltage or current outputs may require thicker wire gauges to handle the increased load and prevent overheating or power loss.

- Safety considerations: Ensure that the selected wire gauge can safely handle the electrical current without becoming excessively hot or posing a risk of overheating. Refer to wire ampacity charts or consult with a qualified electrician to determine the safe current-carrying capacity for the chosen gauge.

- System efficiency: Thicker wire gauges have lower resistance, resulting in more efficient power transmission. Consider using a gauge that strikes a balance between current requirements and wire thickness to optimize system efficiency.

It’s important to note that the American Wire Gauge (AWG) system is commonly used to denote wire sizes, with smaller gauge numbers representing thicker wires. As a general guideline, for low-voltage electroculture applications, AWG 14 to 18 gauge wires are typically sufficient. However, for higher current requirements or longer distances, you may need to use thicker wires, such as AWG 10 or lower.

Always consult relevant electrical codes, standards, and safety guidelines when selecting wire gauges for electroculture. If you’re uncertain, it’s advisable to seek advice from an electrician or a qualified professional to ensure the proper selection and installation of the copper wire for your electroculture system.

Buy Our Handcrafted Electroculture Video Course Now…

5 Ways Copper Wire Can Improve Plant Growth

Copper wire is a versatile tool that can be used in various ways to improve plant growth. This article will delve into five key ways in which copper wire can positively impact the growth and well-being of plants. By exploring these innovative methods, gardeners and plant enthusiasts can discover new ways to enhance the health and vitality of their greenery. From promoting root development to deterring pests, copper wire proves to be a valuable addition to any gardening toolkit.

1. Copper as a Micronutrient for Plants

Copper is an essential micronutrient for plants that plays a crucial role in various physiological processes. It acts as a cofactor for numerous enzymes involved in photosynthesis, respiration, and the formation of plant cell walls. Additionally, copper aids in the activation of proteins that help in the uptake of other nutrients such as iron.

- Photosynthesis Support: Copper is vital for photosynthesis as it is a component of plastocyanin, a protein involved in electron transport within chloroplasts. This process is essential for the conversion of sunlight into energy, ultimately fueling plant growth.

- Respiration Enhancement: Copper is also necessary for the function of cytochrome c oxidase, an enzyme crucial for the electron transport chain in plant respiration. This ensures efficient energy production, which is essential for various metabolic processes in plants.

- Iron Uptake Facilitation: Copper plays a role in the activation of enzymes responsible for the synthesis of lignin, a compound found in plant cell walls. This process enhances the structural integrity of plants and promotes growth and development.

In conclusion, by providing plants with the necessary copper micronutrient, you can enhance their photosynthetic efficiency, improve nutrient uptake, and support overall growth and development.

2. The role of copper in photosynthesis

Copper plays a crucial role in photosynthesis, the process by which plants convert light energy into chemical energy to fuel their growth and development. Here are some key ways in which copper contributes to this fundamental process:

- Enzyme activation: Copper is a cofactor for enzymes involved in various stages of photosynthesis, such as plastocyanin in the electron transport chain, which helps transport electrons within the chloroplast. Without copper, these enzymes would not be able to function efficiently, leading to a decrease in overall photosynthetic efficiency.

- Chlorophyll production: Copper is essential for the synthesis of chlorophyll, the pigment responsible for capturing light energy during photosynthesis. Without an adequate supply of copper, plants may struggle to produce sufficient chlorophyll, hindering their ability to absorb sunlight and convert it into energy.

- Oxygen evolution: During photosynthesis, plants release oxygen as a byproduct of splitting water molecules. Copper-containing enzymes like cytochrome c oxidase play a vital role in this process by facilitating electron transfer and oxygen evolution in the chloroplast.

- Stress protection: Copper also helps plants cope with environmental stressors that can affect photosynthetic efficiency, such as high light intensity or fluctuating temperatures. Copper-containing proteins act as antioxidants, scavenging harmful free radicals generated during photosynthesis and protecting the plant from oxidative damage.

- Overall efficiency: By supporting enzyme activity, chlorophyll synthesis, oxygen evolution, and stress protection, copper plays a multifaceted role in optimizing photosynthetic efficiency. Ensuring an adequate supply of copper in the soil can help enhance plant growth and productivity by maximizing their ability to harness light energy for photosynthesis.

In conclusion, copper is a critical micronutrient for plants, particularly in the context of photosynthesis. Its diverse functions within the chloroplast highlight the importance of maintaining optimal copper levels for supporting healthy and productive plant growth.

3. Copper’s impact on plant metabolism

Copper plays a crucial role in improving plant metabolism in several ways:

- Enzyme activation: Copper is an essential component of various enzymes that are involved in metabolic processes within plants. These enzymes play a key role in photosynthesis, respiration, and the synthesis of important molecules like chlorophyll.

- Photosynthesis enhancement: Copper is a critical element in the process of photosynthesis. It aids in electron transfer during photosystem reactions, leading to increased energy production in plants.

- Nutrient absorption: Copper assists in the uptake of other essential nutrients by plants, such as iron and nitrogen. This improved nutrient absorption helps plants maintain healthy growth and development.

- Oxygen reduction: Copper-containing enzymes are involved in reducing oxygen during respiration, which is essential for energy production in plant cells. This process is vital for overall plant metabolism and growth.

- Antioxidant properties: Copper helps plants combat oxidative stress by acting as an antioxidant. It helps neutralize harmful free radicals, protecting plant cells from damage and promoting overall plant health.

Overall, the presence of copper in plant tissues positively influences various metabolic pathways, leading to improved growth, development, and stress tolerance in plants.

4. Copper’s role in enzyme activity

Copper is an essential micronutrient that plays a crucial role in enzyme activity within plants. Enzymes are protein molecules that act as catalysts, speeding up chemical reactions necessary for plant growth and development. Copper is a cofactor for many enzymes involved in various physiological processes essential for plants.

How does copper support enzyme activity in plants?

- Photosynthesis: Copper is a key component of plastocyanin, an enzyme involved in the electron transport chain of photosynthesis. This enzyme helps in the transfer of electrons, contributing to the production of ATP and NADPH, vital energy sources for plants.

- Respiration: Copper is also necessary for cytochrome c oxidase, an enzyme involved in the final step of the electron transport chain in respiration. This enzyme plays a critical role in ATP synthesis, providing energy for plant growth.

- Lignin synthesis: Copper is a cofactor for laccase, an enzyme responsible for lignin formation in cell walls. Lignin provides structural support to plants, enabling them to withstand environmental stressors and stand upright.

- Reactive oxygen species (ROS) regulation: Copper-containing enzymes such as superoxide dismutase help plants regulate ROS levels, preventing cellular damage caused by oxidative stress.

In summary, copper is indispensable for enzyme activity in plants, affecting processes like photosynthesis, respiration, lignin synthesis, and ROS regulation. Ensuring an adequate supply of copper can enhance these enzymatic reactions, leading to improved plant growth and overall health.

5. How copper improves plant immune system

Copper plays a vital role in enhancing the immune system of plants, resulting in improved growth and overall health. Here are a few ways in which copper contributes to boosting the plant’s immune system:

- Antioxidant activity: Copper acts as a cofactor for enzymes involved in the plant’s antioxidant defense system. These enzymes help the plant combat oxidative stress caused by environmental factors such as pollution, UV radiation, and pathogens.

- Pathogen defense: Copper ions have antimicrobial properties, making them effective in fighting off harmful pathogens like fungi and bacteria. By incorporating copper into their defense mechanisms, plants can better resist diseases and infections.

- Enhanced enzyme activity: Copper is essential for the activation of enzymes that play a crucial role in plant defense responses. These enzymes help in triggering immune responses when the plant is under attack, improving its ability to ward off diseases.

- Cell wall reinforcement: Copper aids in the synthesis of lignin, a component of the plant cell wall that provides structural support and protection. A stronger cell wall acts as a physical barrier against pathogens and helps the plant maintain its structural integrity.

- Regulation of gene expression: Copper influences the expression of genes related to stress responses and immune functions in plants. By regulating gene expression, copper helps plants adapt to changing environmental conditions and effectively respond to stressors.

Incorporating copper wire in the soil or using copper-based fungicides can help enhance the plant’s immune system, leading to healthier and more resilient growth. By harnessing the immune-boosting properties of copper, growers can promote better plant health and productivity in their fields or gardens.

Refer This Copper Antennas For Electroculture….

Last update on 2024-06-28 / Affiliate links / Images from Amazon Product Advertising API

Final Words

It is important to note that the gauge of wire is only one factor that determines the amount of current that can flow through it. The length of the wire is also a factor. The longer the wire, the more resistance it will have, which will reduce the amount of current that can flow through it.

If you are unsure of the amount of current you need, it is always best to err on the side of caution and use a thicker wire. It is also a good idea to consult with an electrician if you are planning on running a large amount of current.

Here are some additional tips for selecting copper wire for electroculture:

- Use solid core wire instead of stranded wire. Solid core wire is more durable and will last longer.

- Choose a wire that is made of high-quality copper. This will ensure that the wire is resistant to corrosion and will last for many years.

- Insulate the ends of the wire with heat shrink tubing or electrical tape. This will prevent the wire from arcing and causing a fire.

With proper care, copper wire can be a valuable tool for electroculture. By selecting the right gauge of wire and using high-quality materials, you can ensure that your electroculture system will last for many years.

Buy Your Electroculture Books Fro Here...