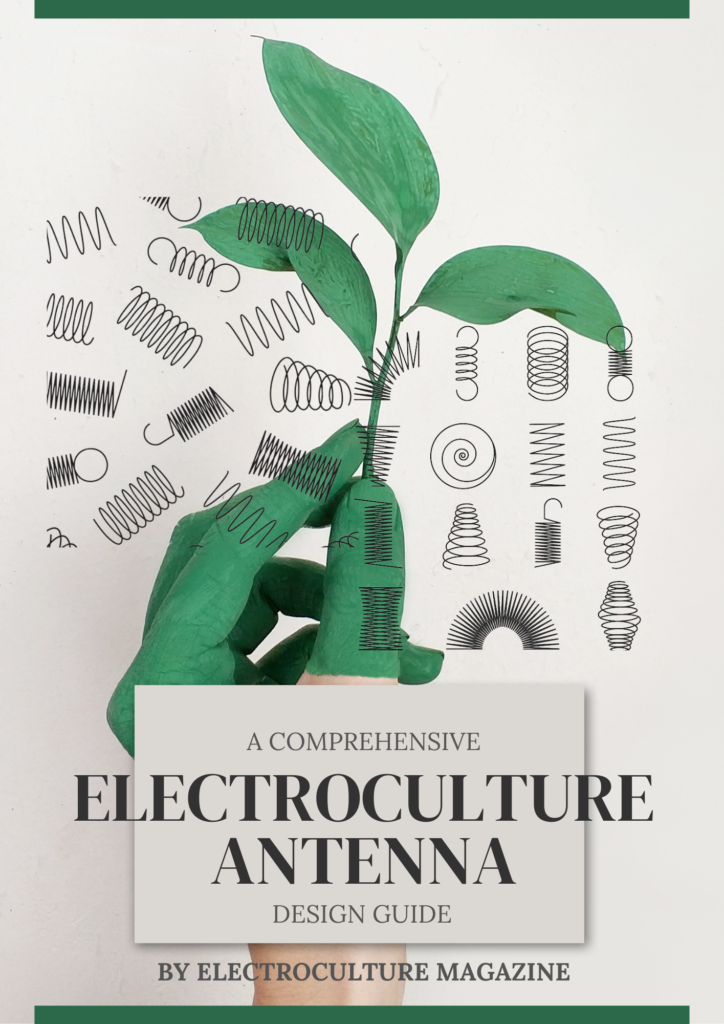

Electroculture antennas are essential components in agriculture, utilizing electromagnetic fields to enhance plant growth and health. These antennas emit frequencies that stimulate plant metabolism, leading to increased nutrient uptake and overall crop productivity. Understanding the significance of electro culture antennas in modern agriculture is crucial for optimizing farming practices. In this article we will review the best metals for electroculture antennas.

Best Metals for Electroculture Antennas

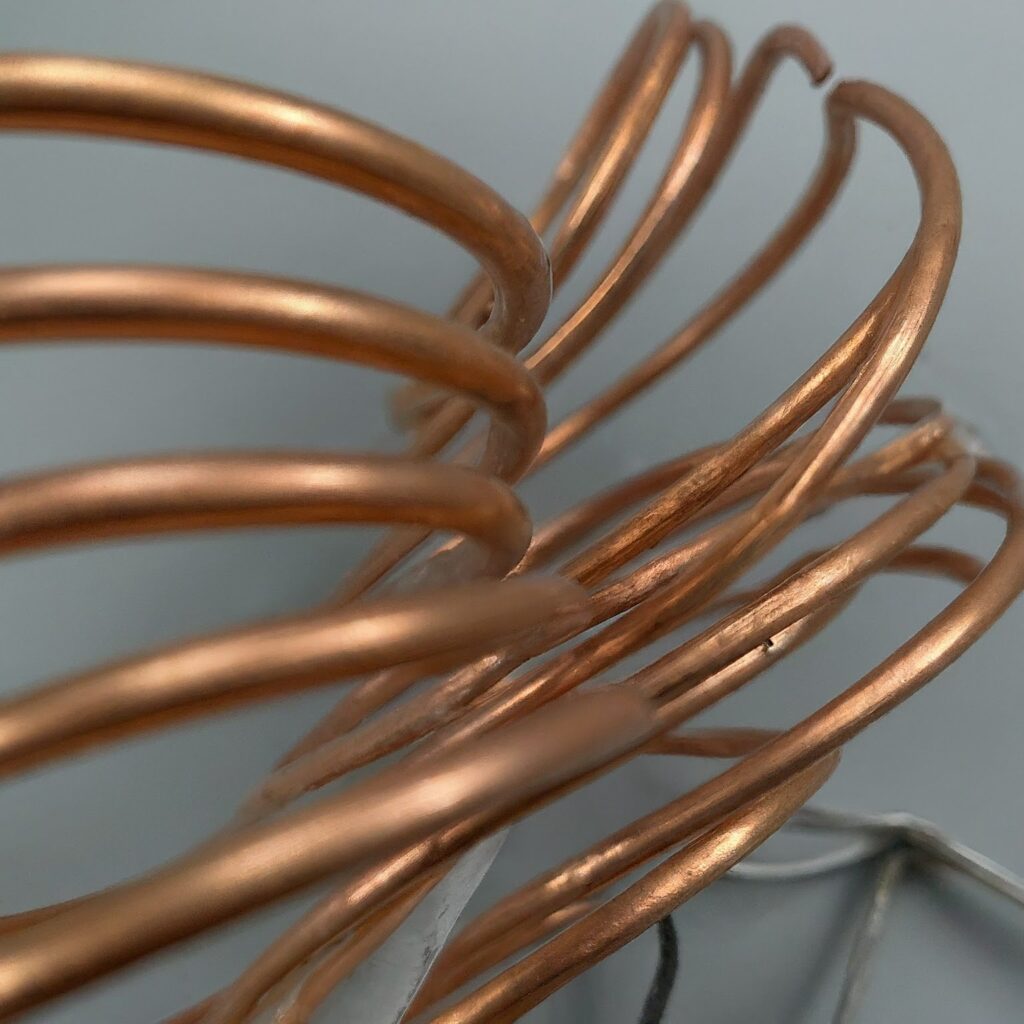

Metals with certain characteristics are needed for electroculture antennas to maximise their ability to promote plant growth. Copper is one of the leading candidates because of its exceptional conductivity and corrosion resistance, which are crucial for sustaining antenna performance over time. Aluminium is an economical and reasonably conductive material that may be used in large-scale applications.

Titanium is highly valued for its resilience to environmental influences and long life under difficult circumstances. Furthermore, gold has unmatched conductivity, which makes it perfect for high-precision applications even if it is pricey. The investigation of these metals in electroculture antennas holds the potential to provide sustainable and effective ways to improve plant development through technological improvements in agriculture.

Key Points:

- Electro culture antennas harness electromagnetic waves to influence plant growth positively.

- The antennas emit specific frequencies that trigger biochemical reactions within plants.

- Increased nutrient absorption and improved plant resistance to diseases are among the benefits of using electro culture antennas.

- Farmers can enhance crop yield and quality by implementing electro culture antennas in their fields.

By exploring different metals for electro culture antennas, researchers and farmers can identify the most effective materials to achieve optimal plant stimulation. The selection of metals plays a vital role in the efficiency and performance of electro culture antennas. With the right materials, farmers can harness the power of electromagnetic fields to revolutionize modern agriculture practices and cultivate healthier, more abundant crops.

The Importance of Metal Selection for Antennas

When it comes to electro culture antennas, the selection of the right metal plays a crucial role in their performance and effectiveness. Here are some key points highlighting the importance of metal selection for antennas:

- Conductivity: The metal used in an antenna must have high conductivity to ensure efficient transmission and reception of electromagnetic signals.

- Durability: Choosing a metal that is durable and can withstand harsh environmental conditions is essential for the longevity of the antenna.

- Corrosion Resistance: Antennas are often exposed to outdoor elements, so selecting a metal with good corrosion resistance can prevent degradation over time.

- Weight: The weight of the metal used can impact the overall weight and portability of the antenna, making it important to strike a balance between strength and weight.

- Cost: The cost of the metal chosen for the antenna can also be a factor, especially when considering large-scale deployment of antennas.

In conclusion, the metal selection for electro culture antennas is a critical decision that can significantly impact the performance, durability, and cost-effectiveness of the antennas. By carefully considering factors such as conductivity, durability, corrosion resistance, weight, and cost, antenna designers can ensure that they choose the best metal for their specific application.

Factors to Consider When Choosing Metals for Electro culture Antennas

- Conductivity: Select metals with high conductivity, such as copper or aluminum, for efficient energy transmission and reception.

- Corrosion Resistance: Opt for metals with excellent corrosion resistance to withstand outdoor elements. Stainless steel or copper alloys are good choices in this regard.

- Durability: Choose metals that are durable and can endure exposure to environmental factors without degradation, ensuring longevity of the antenna.

- Cost-Effectiveness: Consider the cost of the metal in relation to its performance and longevity to make a cost-effective choice for your electro culture antenna.

- Flexibility: Some metals offer flexibility in design and shaping, which can be advantageous when building custom antenna configurations.

- Weight: The weight of the metal can impact the installation and stability of the antenna, so choose a metal that strikes a balance between strength and weight.

- Availability: Ensure the chosen metal is readily available for sourcing, fabrication, and potential future repairs or modifications.

- Compatibility: Consider the compatibility of the metal with other materials used in the antenna construction to prevent any issues with galvanic corrosion.

- Environmental Impact: Assess the environmental impact of the metal production and disposal to make an eco-friendly choice for your electro culture antenna.

- Conductivity: The selected metal should have high conductivity to ensure efficient transmission and reception of energy in electro culture systems.

- Corrosion Resistance: Opt for metals with excellent corrosion resistance to ensure longevity and durability, particularly in outdoor installations.

- Durability: Choose metals that are durable and can withstand environmental factors to maintain consistent performance over time.

Common Metals For Electroculture Antennas

Copper is a common metals for electroculture antennas because of its excellent conductivity and corrosion resistance, which make it a dependable material for long-term performance. Because of its reasonable cost and acceptable conductivity, aluminium is also a well-liked material for widespread use in electroculture systems. Furthermore, stainless steel is preferred because of its rust resistance and lifespan in outdoor settings. These metals are essential for building antennas that use electrical energy to stimulate plant growth. This helps to increase crop yields and support sustainable farming practices.

Common Metals For Electroculture Antennas

- Copper: Copper is one of the most common metals used in electro culture antennas due to its excellent conductivity and resistance to corrosion. It is ideal for antennas that require high efficiency and performance.

- Aluminum: Aluminum is another popular choice for electro culture antennas as it offers good conductivity, lightweight properties, and affordability. It is often used in larger antennas where weight is a concern.

- Stainless Steel: Stainless steel is chosen for electro culture antennas that require durability and resistance to harsh environmental conditions. It is a sturdy metal that can withstand exposure to the elements.

- Galvanized Steel: Galvanized steel is a cost-effective option for electro culture antennas. It is treated with a protective zinc coating to prevent rust and corrosion, making it suitable for outdoor use.

- Brass: Brass is sometimes used in electro culture antennas for its combination of good conductivity and aesthetic appeal. It is a durable metal that can enhance the look of an antenna.

- Bronze: Bronze is less common but offers good conductivity and resistance to corrosion, making it suitable for antennas that need to withstand challenging weather conditions.

- Nickel: Nickel is occasionally used in electro culture antennas for its magnetic properties and resistance to corrosion. It can be a suitable choice for specialized antenna applications.

In conclusion, selecting the right metal for an electro culture antenna depends on factors such as conductivity, durability, cost, and environmental conditions. Each metal has its own advantages and considerations, so it is essential to choose wisely based on the specific requirements of the antenna being designed.

Advantages and Disadvantages of Different Metals

- Copper:

- Advantages:

- Excellent conductive properties for efficient signal transmission.

- Resistant to corrosion, enhancing longevity.

- Easy to work with due to its malleability.

- Disadvantages:

- Relatively expensive compared to other metals.

- Prone to theft due to high scrap value.

- Advantages:

- Aluminum:

- Advantages:

- Lightweight, making it easier to install.

- Lower cost compared to copper.

- Good conductivity for signal transmission.

- Disadvantages:

- More susceptible to corrosion than copper.

- Less malleable, which can make shaping and connecting more challenging.

- Advantages:

- Galvanized Steel:

- Advantages:

- Affordable option for antennas.

- Strong and durable, suitable for outdoor use.

- Good corrosion resistance with proper coating.

- Disadvantages:

- Heavier than aluminum and copper, making installation cumbersome.

- Susceptible to rust if coating is compromised.

- Advantages:

- Stainless Steel:

- Advantages:

- Excellent corrosion resistance for long-term use.

- High strength, suitable for robust antenna structures.

- Low maintenance requirements.

- Disadvantages:

- More expensive compared to other metals.

- Lower conductivity, potentially affecting signal quality.

- Advantages:

- Brass:

- Advantages:

- Good corrosion resistance.

- Attractive appearance for decorative purposes.

- Relatively easy to machine.

- Disadvantages:

- Lower conductivity compared to copper.

- Can tarnish over time, requiring maintenance.

- Advantages:

By understanding the advantages and disadvantages of different metals commonly used for electroculture antennas, one can make an informed decision based on their specific needs and priorities.

Impact of Metal Conductivity on Antenna Performance

- Different metals possess varying levels of conductivity, which can significantly impact the performance of electro culture antennas.

- High conductivity metals like copper and silver are ideal for antennas as they allow for efficient transmission and reception of electromagnetic signals.

- Metals with low conductivity, such as aluminum or steel, may result in higher resistance and signal loss in antenna systems.

- The choice of metal for an antenna can affect its overall efficiency and effectiveness in capturing and transmitting electromagnetic waves.

- Conductivity plays a crucial role in determining the range, sensitivity, and signal clarity of an antenna system.

- Antennas made from highly conductive metals tend to have better performance in terms of signal strength and reception quality.

- Using metals with lower conductivity may result in poor antenna performance, requiring more power input to achieve the desired signal output.

- When selecting metals for electro culture antennas, it is essential to consider the conductivity levels to optimize the antenna’s performance.

- Conductivity not only influences the efficiency of the antenna but also affects its durability and longevity in different environmental conditions.

Overall, the conductivity of the metal used in electro culture antennas directly impacts their performance and effectiveness in capturing and transmitting electromagnetic signals.

Learn All About Electrcoulture Antenna, A Comprehensive ELECTROCULTURE ANTENNA Design Guide,

Corrosion Resistance of Metals in Electro culture Antennas

- Stainless steel is a popular choice for electro culture antennas due to its excellent corrosion resistance.

- Copper is another metal known for its resistance to corrosion, making it a reliable option for antennas in varying environments.

- Aluminum is lightweight and corrosion-resistant, but it may require additional surface treatments for enhanced protection in harsh conditions.

- Titanium offers superior corrosion resistance and strength, making it ideal for long-lasting antennas, although it is more expensive than other metals.

- Proper maintenance and periodic inspections are essential to ensure the longevity and performance of electro culture antennas, regardless of the metal used.

Corrosion resistance plays a crucial role in the durability of metals used in electro culture antennas, protecting them from environmental factors that can cause deterioration over time.

Optimal Metal Combinations for Enhanced Antenna Performance

When it comes to electro culture antennas, choosing the right metal combinations is crucial for achieving optimal performance. Several metals have been found to work exceptionally well together in enhancing antenna functionality. Here are some of the best metal combinations for improved antenna performance:

- Copper and Aluminum: Combining copper, known for its excellent conductivity, with aluminum, which is lightweight and cost-effective, can result in an antenna that offers a good balance between performance and affordability.

- Silver and Gold: While silver and gold are more expensive metals, they have superior conductivity properties. Combining these metals can create high-performance antennas that are particularly effective in environments with high electromagnetic interference.

- Copper and Nickel: Nickel is known for its magnetic properties, which can complement the excellent conductivity of copper. Combining these two metals can result in antennas that are not only efficient but also more resistant to interference.

- Aluminum and Titanium: Titanium is a strong and corrosion-resistant metal that, when combined with aluminum, can create antennas with durability and stability. This combination is ideal for outdoor antennas exposed to harsh weather conditions.

- Copper and Zinc: Zinc, although not as conductive as copper, offers good corrosion resistance. Pairing copper with zinc can result in antennas that are durable and suitable for long-term use in various environments.

By carefully selecting and combining these metal pairs based on the specific requirements of the antenna application, it is possible to enhance antenna performance significantly. It is important to consider factors such as conductivity, cost, durability, and environmental conditions when choosing the optimal metal combinations for electro culture antennas.

Case Studies: Successful Applications of Specific Metals in Antennas

- Copper:

- Copper is widely used in antennas due to its excellent conductivity and stability.

- Several studies have shown that copper antennas have high efficiency and reliability.

- Copper antennas are known for their durability and resistance to corrosion.

- Aluminum:

- Aluminum antennas are popular for their lightweight properties and ease of fabrication.

- Research has demonstrated that aluminum antennas can achieve good performance at a lower cost.

- Aluminum is a cost-effective option for antennas in various applications.

- Gold:

- Gold-plated antennas offer superior conductivity and resistance to oxidation.

- Gold antennas are used in high-frequency applications where signal purity is crucial.

- Although more expensive, gold antennas provide excellent performance in specialized settings.

- Silver:

- Silver is valued for its high conductivity and thermal stability in antennas.

- Studies have shown that silver-coated antennas have low signal loss and high accuracy.

- Silver antennas are commonly utilized in precision measurement and communication systems.

- Titanium:

- Titanium antennas are recognized for their strength, lightweight design, and corrosion resistance.

- Research indicates that titanium antennas can withstand harsh environmental conditions.

- Titanium offers a combination of durability and performance for rugged antenna requirements.

- Stainless Steel:

- Stainless steel antennas are known for their robustness and suitability for outdoor applications.

- Stainless steel is corrosion-resistant and provides longevity in antenna installations.

- Stainless steel antennas are a reliable choice for high-wind areas and challenging environments.

These case studies highlight the successful applications of specific metals in antennas, showcasing their unique properties and advantages for various antenna designs and requirements.

Future Trends in Metal Usage for Electro culture Antennas

- Advancements in Material Science:

- Scientists are continuously researching new metal alloys that offer improved conductivity and durability for electro culture antennas.

- Nanotechnology is being explored to enhance the properties of metals used in antenna production.

- Focus on Sustainability:

- There is a growing trend towards using eco-friendly metals that can be easily recycled, reducing the environmental impact of antenna manufacturing.

- Biodegradable metals are being developed as a future alternative for sustainable antenna production.

- Integration of Smart Materials:

- Smart metals with self-healing properties are being studied for use in antennas, increasing their longevity and reducing maintenance costs.

- Shape memory alloys that can adapt to changing environmental conditions are being considered for future antenna designs.

- Collaboration with Other Industries:

- Collaboration with the electronics industry is becoming more common to develop antennas that can integrate seamlessly with other technological devices.

- Metal manufacturers are partnering with aerospace companies to leverage lightweight yet sturdy materials for antenna construction.

- Exploration of Alternative Metals:

- Titanium and aluminum are emerging as potential substitutes for traditional copper antennas due to their lightweight nature and resistance to corrosion.

- Composite metals, such as carbon fiber reinforced polymers, are being investigated for their high strength-to-weight ratio, providing a promising future for antenna materials.

Best Practices for Maintaining Metal Antennas

- Regular Inspection: Check the antenna regularly for any signs of damage, corrosion, or loose connections. Address any issues promptly to prevent further damage.

- Cleaning: Clean the metal antenna regularly to remove dust, dirt, and debris that can affect its performance. Use a soft cloth or a non-abrasive cleaning solution to avoid scratching the metal surface.

- Weather Protection: If the metal antenna is installed outdoors, consider adding a weatherproof coating to protect it from the elements. This can help prevent rust and corrosion, extending the lifespan of the antenna.

- Grounding: Ensure that the metal antenna is properly grounded to prevent electrical hazards and interference. Consult a professional or follow the manufacturer’s guidelines for proper grounding techniques.

- Avoiding Physical Damage: Be mindful of any activities or objects that may cause physical damage to the metal antenna. Keep it out of reach of children, pets, or any potential hazards.

- Professional Maintenance: Consider hiring a professional technician to inspect and maintain the metal antenna periodically. They can identify potential issues early on and provide expert recommendations for optimal performance.

- Storage: If the metal antenna needs to be stored for an extended period, ensure it is kept in a dry and secure location. Use protective coverings to prevent dust accumulation and minimize the risk of damage.

- Documentation: Keep detailed records of any maintenance or repairs performed on the metal antenna. This information can help track its performance over time and assist in troubleshooting any future issues.

- Testing: Conduct regular performance tests on the metal antenna to ensure it is functioning correctly. Monitor signal strength, connectivity, and any other relevant metrics to detect any deviations from the expected performance.

Comparison of Metals for Different Types of Electro culture Antennas

- Copper:

- Excellent conductivity for enhanced signal strength.

- Resistant to corrosion, ensuring longevity.

- Relatively expensive compared to other metals.

- Aluminum:

- Lightweight and cost-effective.

- Good conductivity but not as efficient as copper.

- Prone to corrosion in certain environments.

- Steel:

- Strong and durable, suitable for larger antennas.

- Moderately conductive, but not as efficient as copper or aluminum.

- Susceptible to rust, requiring regular maintenance.

- Gold:

- Extremely high conductivity for optimal signal transmission.

- Very expensive and often impractical for large-scale antennas.

- Limited availability and often used for specialized purposes.

- Silver:

- Excellent conductivity, second only to gold.

- Relatively costly, but more affordable than gold.

- Sensitive to sulfur compounds in the atmosphere, leading to tarnishing.

Each metal offers unique characteristics that can impact the performance and cost-effectiveness of electro culture antennas. The choice of metal should be based on factors such as budget, environmental conditions, and desired signal strength.

Effect of Metal Purity on Antenna Efficiency

When it comes to electro culture antennas, the purity of the metal used can have a significant impact on the overall efficiency of the antenna. Here are some key points to consider regarding the effect of metal purity on antenna efficiency:

- Conductivity: The purity of the metal directly affects its conductivity, which is crucial for the efficient functioning of an antenna. Higher purity metals typically have better conductivity, allowing for better signal transmission and reception.

- Resistance: Impurities in the metal can increase resistance, leading to energy loss in the form of heat. This can reduce the overall efficiency of the antenna, as some of the energy that should be transmitted or received is instead dissipated as heat.

- Corrosion: Metals with higher purity levels are often more resistant to corrosion, which can degrade the performance of the antenna over time. Using a high-purity metal can help ensure the longevity and reliability of the antenna.

- Signal Quality: The purity of the metal can also impact the quality of the signals transmitted and received by the antenna. Higher purity metals tend to provide better signal clarity and strength, leading to improved overall performance.

- Cost: It is important to consider the cost implications of using high-purity metals for electro culture antennas. While higher purity metals may offer better performance, they can also be more expensive. Balancing cost and performance is key when selecting the best metal for an antenna.

In summary, the purity of the metal used in electro culture antennas plays a crucial role in determining their efficiency and performance. By choosing high-purity metals, practitioners can ensure optimal conductivity, reduced resistance, improved signal quality, and enhanced durability for their antennas.

Cost Considerations in Metal Selection

When selecting the metal for electroculture antennas, cost considerations play a significant role. Different metals come with varying price points, making it essential to factor in the budget for the project. Here are some key points to consider regarding cost when choosing a metal for electroculture antennas:

- Initial Cost: The upfront cost of purchasing the metal is a crucial factor to consider. Some metals like copper and silver are more expensive than others like aluminum or steel. Depending on the budget allocated for the project, the initial cost of the metal can impact the overall feasibility.

- Durability and Maintenance: While the upfront cost is important, it is also essential to consider the durability of the metal. Opting for a cheaper metal that requires frequent maintenance or replacement may end up being more costly in the long run. Balancing the initial cost with the durability and maintenance requirements is crucial in making a cost-effective choice.

- Performance and Longevity: The performance of the metal in the application, as well as its longevity, can also affect the overall cost. A more expensive metal that offers better conductivity and longevity may prove to be a cost-effective choice over time compared to a cheaper alternative that needs to be replaced more frequently.

- Availability and Market Trends: The availability of the metal in the market and any trends in pricing should also be considered. Prices of metals can fluctuate based on market demand, supply, and other external factors. It is advisable to have a good understanding of the market trends before making a decision on the metal selection.

Considering these cost factors alongside the specific requirements and constraints of the electroculture antenna project can help in choosing the most suitable and cost-effective metal for optimal performance and longevity.

Environmental Implications of Metal Usage in Antennas

- Metals used in antennas have environmental implications due to the extraction and processing methods involved.

- Mining for metals like copper and aluminum can lead to habitat destruction, soil erosion, and water pollution.

- The energy-intensive processes of refining and smelting metals contribute to greenhouse gas emissions and air pollution.

- Improper disposal of metal-containing electronic waste from old antennas can contaminate soil and water sources.

- Choosing metals with lower environmental impacts, such as recycled aluminum or copper, can help reduce the ecological footprint of antenna production.

- Designing antennas with longevity in mind can decrease the frequency of replacement, further minimizing metal usage and waste generation.

- Implementing proper recycling programs for old antennas can ensure that valuable metals are recovered and reused, reducing the need for new metal extraction.

- Research into alternative materials for antennas, such as carbon nanotubes or biodegradable polymers, holds promise for reducing reliance on traditional metals with high environmental costs.

Metal Recycling and Sustainability in Electro culture Antennas

- Metal recycling is a crucial aspect of sustainability in electro culture antennas.

- By recycling metals, less energy is required compared to extracting new metals from ores.

- Recycling helps reduce greenhouse gas emissions and lessens the environmental impact of metal production.

- Copper is commonly used in electro culture antennas due to its excellent conductivity and corrosion resistance.

- Aluminum is another popular choice for its lightweight properties and affordability.

- Stainless steel is favored for its durability and resistance to corrosion in harsh outdoor environments.

- Brass is sometimes used in electro culture antennas for its aesthetic appeal and decent conductivity.

- The recycling process for these metals involves collecting, sorting, melting, and purifying the metal scrap.

- Recycled metal retains its properties and can be reused in new antenna components.

- Sustainable practices in metal recycling contribute to a more environmentally friendly electro culture antenna industry.

Regulatory Compliance and Metal Standards for Antennas

When it comes to electro culture antennas, regulatory compliance and adherence to metal standards are essential aspects to consider. Here are some key points to keep in mind:

- FCC Regulations: The Federal Communications Commission (FCC) regulates the use of antennas to ensure they meet safety and interference standards. It is crucial to comply with FCC guidelines when designing and using electro culture antennas.

- Metal Standards: The choice of metal for antennas is critical for performance and durability. Common metals used for antennas include copper, aluminum, and stainless steel. These metals offer different conductivity and rust resistance properties, which can impact the antenna’s efficiency.

- Corrosion Resistance: Antennas are often exposed to harsh weather conditions, which can accelerate corrosion. Using metals with high corrosion resistance, such as stainless steel or aluminum alloys, can prolong the antenna’s lifespan and maintain its performance over time.

- Environmental Regulations: Certain metals used in antennas may be subject to environmental regulations due to their impact on ecosystems and human health. It is important to choose metals that meet environmental standards and regulations to mitigate any negative consequences.

- Industry Standards: Apart from regulatory compliance, following industry standards such as those set by the Institute of Electrical and Electronics Engineers (IEEE) can ensure the reliability and performance of electro culture antennas. These standards provide guidelines for metal selection, design, and testing procedures.

Ensuring regulatory compliance and adhering to metal standards are crucial steps in designing and using electro culture antennas that are safe, efficient, and sustainable. By carefully selecting metals and following relevant regulations, antenna designers can optimize performance while meeting legal and environmental requirements.

Research and Development in Metal Alloys for Improved Antenna Performance

- Researchers are constantly exploring novel metal alloys to enhance the performance of electro culture antennas.

- The aim is to identify materials that offer better conductivity, durability, and resistance to environmental factors.

- By tweaking the composition of metal alloys, scientists can fine-tune antenna characteristics like signal strength and frequency range.

- Advanced simulation tools help in predicting the behavior of different alloys under varying conditions, aiding in the selection process.

- Continuous experimentation and testing are crucial to validate the theoretical performance of new metal alloys in real-world antenna applications.

- Collaboration between material scientists, engineers, and antenna designers is key to developing optimized metal alloys for antennas.

- Factors such as cost-effectiveness and ease of manufacturing also play a role in determining the practicality of using specific metal alloys.

“Innovation in metal alloy research paves the way for next-generation antennas with superior performance and reliability.”

Case Studies: Failures Caused by Incorrect Metal Selection

- Stainless steel antennas were subject to corrosion due to exposure to salty environments, leading to a decrease in performance over time.

- Aluminum antennas showed signs of degradation when exposed to acidic soils, affecting conductivity and overall efficiency.

- Copper antennas experienced oxidization when in contact with moisture, resulting in a diminished signal transmission capability.

- Brass antennas suffered from galvanic corrosion when paired with incompatible mounting hardware, causing structural integrity issues.

These case studies highlight the importance of selecting the right metal for electro culture antennas to ensure longevity and optimal performance.

Conclusion and Recommendations for Choosing the Best Metals for Electro culture Antennas

- Aluminum proved to be a suitable metal for electro culture antennas due to its lightweight and corrosion resistance.

- Copper exhibited excellent conductivity, making it a top choice for electro culture antennas.

- Stainless steel, although durable and able to withstand harsh environments, may not provide the same level of conductivity as copper.

- When selecting a metal for electro culture antennas, consider factors such as conductivity, durability, and cost.

- It is recommended to prioritize conductivity when choosing a metal for electro culture antennas to ensure optimal performance.

- Regular maintenance and inspection of electro culture antennas are essential to ensure longevity and efficiency.

- Experimenting with different metals or metal combinations may be beneficial to determine the most effective option for specific electro culture antenna applications.